SOLUCIONES A MEDIDA

Fabricamos equipos personalizados concebidos para la mezcla y envasado de productos sólidos o líquidos y viscosos.

Desde el pasado mes de marzo de 2021, disponemos de la certificación ISO 9001 como garantía de calidad en todos nuestros procesos.

Mezcladores de sólidos

Fabricamos a medida diferentes mezcladores de sólidos de diversos tipos: Mezcladores bicono, Mezcladores V, Mezcladores container mix, mezcladores horizontales, mezcladores cónicos verticales y muchos otros.

Mezcladores de líquidos

Fabricamos equipos a medida para mezclar, agitar, dosificar, emulsionar y dispersar sustancias líquidas en distintas proporciones. Especialmente diseñados para aplicaciones en industria Farmacéutica, Cosmética y Alimentaria

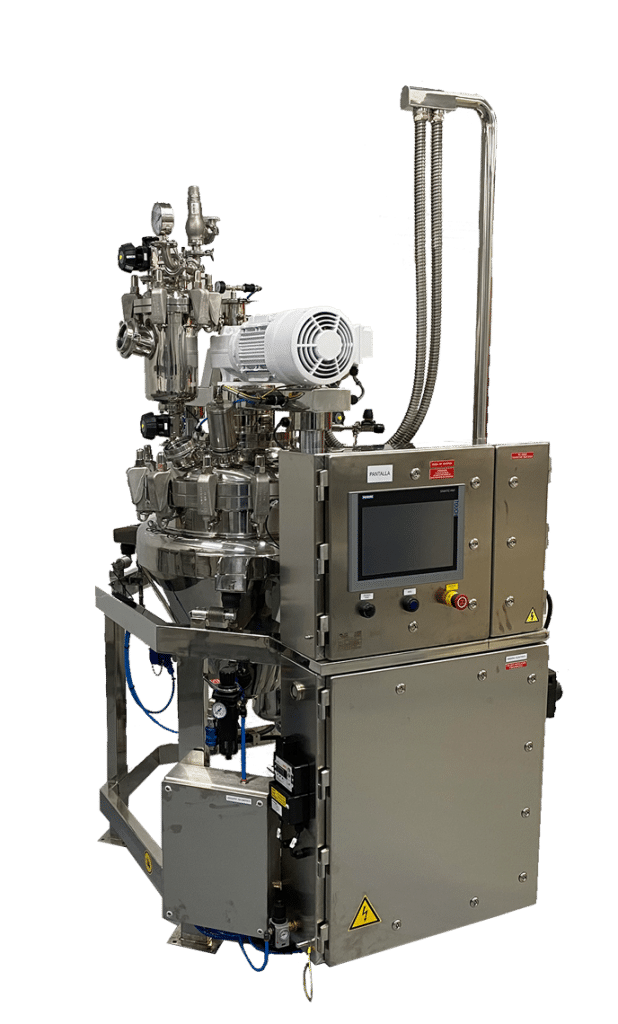

Reactores GMP

Los reactores GMP de IPROCOMSA, están diseñados de acuerdo a las especificaciones de cada cliente para cumplir fielmente con los exigentes requisitos de proceso, además de cumplir con la normativa vigente referente a maquinas destinadas a la elaboración de medicamentos o de alimentos en su caso.

Ensacadora de sólidos

Soluciones y líneas para el envasado de productos polvorientos, con control de peso, dosificación automática en grueso y fino, y automatización parcial o total de la línea.

Envasadora de líquidos

Tenemos soluciones y líneas para el llenado de envases de distinto formato para líquidos y viscosos. Posibilidad de automatización completa de la línea. Equipos diseñados para trabajar con envases desde 0.5l a 1000l. Construcción en entorno ATEX bajo demanda

Skid modulares

Unidades modulares de procesos, con todos aquellos elementos mecánicos, hidráulicos, neumáticos y eléctricos, necesarios para el funcionamiento íntegro de la unidad de proceso integrada. Instalaciones llaves en mano.

Sistemas CIP

Equipos de limpieza diseñados para cumplir con las exigencias de limpieza de los procesos farmacéuticos o alimentarios. Fabricamos desde grandes instalaciones completamente automatizadas a económicos CIP’s portátiles de funcionamiento manual

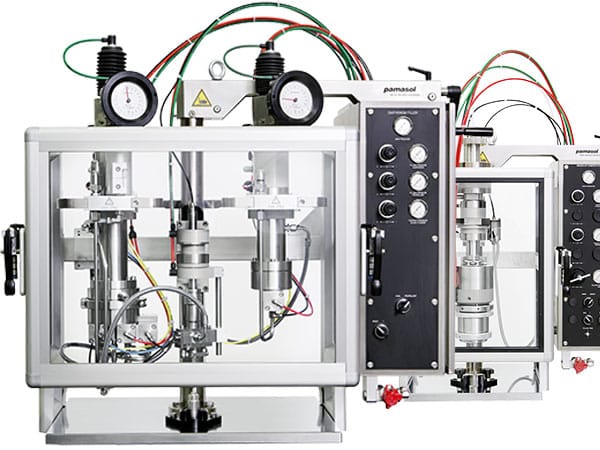

Envasado de aerosoles

Somos representantes exclusivos en España de PAMASOL, firma suiza líder mundial en el envasado de aerosoles.

Maquinaria de proceso

Disponemos también de una amplia gama de equipos auxiliares. Emulsionadores, dispersadores, agitadores tipo turbo, agitadores de productos viscosos, entre otros para aplicaciones con líquidos. Para los procesos con solidos disponemos de tamizadoras, sistemas de transporte de sólidos, entre otros.

SOBRE NUESTROS EQUIPOS

Son equipos concebidos para la mezcla y envasado de productos sólidos o líquidos y viscosos. Los equipos pueden fabricarse para trabajar a presión dentro del cuerpo o bien a presión atmosférica, con cámara de refrigeración o calefacción dependiendo de las necesidades del proceso de fabricación.

QUÉ OFRECEMOS

Aportamos a nuestros clientes soluciones personalizadas en sus procesos de fabricación y envasado, ofreciendo toda nuestra experiencia y conocimiento de procesos, así como la fiabilidad y calidad de la maquinaria diseñada y fabricada íntegramente en nuestras instalaciones.

Asesoramos a nuestros clientes en el diseño inicial de la línea de fabricación y en la elección de la maquinaria más apropiada incluyendo pruebas a medida. Fabricamos conforme los estándares más exigentes de los sectores con los que trabajamos, garantizando calidad, coste, y plazo de entrega, así como toda la documentación necesaria para la posterior validación de la instalación. También realizamos tareas de mantenimiento preventivo y correctivo con nuestros clientes que nos escogen por nuestro conocimiento profundo de la maquinaria.

Tenemos una extensa gama de equipos de mezclado, agitación y dispersión, así como de envasado. Todo ello tanto para sólidos como para líquidos. Abarcamos desde los equipos completamente manuales, hasta los más complejos sistemas automatizados incluyendo instrumentación, programación y control. Todos nuestros equipos llevan el marcado CE, y en caso de necesidad del cliente los podemos certificar para trabajar en entornos potencialmente explosivos (normativa ATEX).